Preparation for Revamping

- Step 1: Documentation and gathering information

Gearbox Identification

- Step 2: Preliminary analysis

Damage and malfuncion identification In this case, the ceramic industry has decided to carry out maintenance because the bearing has exceeded the operating hours specified in the design,....Gearbox produced in 1998 never done nothing before the 2015.

- Step 3: Disassembling the Gearbox

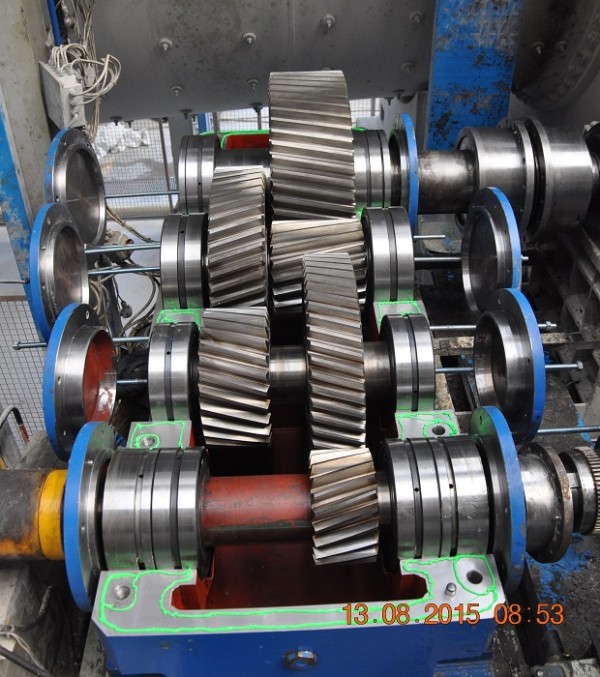

Gearbox open for visual inspection

- Step 4: Replacement and restoration of components

| Gears ready to desmount the bearings | Disassembling the low speed coupling |

|

|

| Desmounting some bearing | Check the backslash before close the gearbox |

|

|

- Step 5: Sealing the gearbox

Sealing the GSM gearbox

- Step 6: Final check and verify the lubrication system

| Forced lubrication system of the gearbox and check | ||

|

|

|

- Step 7: Testing and commissioning

The gearbox was initially tested at a very low speed to check for noise and vibrations. It was then tested at normal operating speed under the mill’s standard load conditions.

-

- Step 8: Planning future maintenance

After replacing all the bearing, the customer is still check with periodically monitor of the bearings after 10 years of operation.

We are very pruod to have done this revamping.

- Step 8: Planning future maintenance

Call us Now at +39 349/3703769 or email to:info@micmrs.com