Preparation for Revamping

- Step 1: Documentation and gathering information

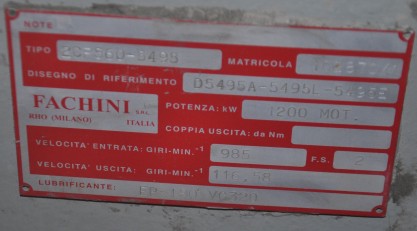

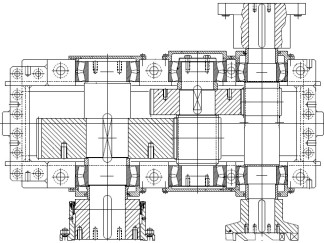

Gearbox Identification Sectional view of the gearbox

- Step 2: Preliminary analysis

Damage and malfuncion identification

- Step 3: Disassembling the Gearbox

Gearbox open for visual inspection

- Step 4: Replacement and restoration of components

| Component to be replaced | Disassembling the wheel |

|

|

| Checking dimensions | Reassembing gear |

|

|

- Step 5: Sealing the gearbox

Sealing upper part of the gearbox

- Step 6: Final check and verify the lubrication system

| Forced lubrication system of the gearbox | |

|

|

|

|

- Step 7: Testing and commissioning

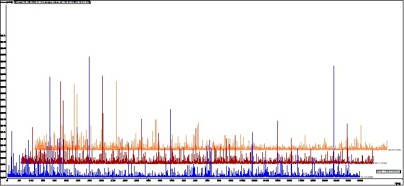

Check the temperature and funcionality Check vibration

-

- Step 8: Planning future maintenance

After replacing the intermediate shaft with new bearings, the customer was advised to periodically monitor the bearings of the slow and fast shafts. Additionally, the installation of the MRS monitoring system was recommended, enabling real-time tracking of key functional parameters of the gearbox, such as vibrations, flow rates, and oil pressures. This proactive approach optimizes predictive maintenance, extending the replacement interval and maximizing the operational efficiency of the plant.

- Step 8: Planning future maintenance

Call us Now at +39 349/3703769 or email to:info@micmrs.com